Special Processes

|

|

|

OTEC CF HYDROLYZED AGGRESSION AND POLISHING MACHINE |

|

| DRUM VOLUME | 18 Litre |

| DRUM DIAMETER | 330 mm |

| EXTERNAL DIMENSIONS | 720x910x1520 mm |

| WEIGHT | 130 kg |

| POWER | 1,2 Kva, 230 V |

|

|

|

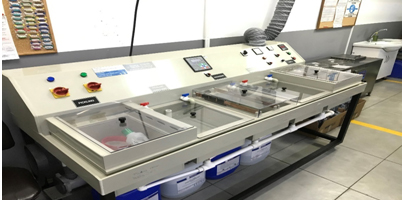

ULTRASONIC WASHING UNIT |

|

| LITRE | 10 L |

| NUMBER OF CHAMBERS | 3 |

| ULTRASONIC WASHING CHAMBER | 45° |

| RINSING CHAMBER | 23° |

| DRYING CHAMBER | 70° |

|

|

|

SAND BLASTER |

|

| TWO SEPARATE SAND CHAMBERS(125-250 micron) | |

| SAND CHAMBER REPLACEMENT VALVE | |

| NON-MOISTURE POLYAMIDE SAND TANKS | |

| INTERNAL VACUUM BINDING FEATURE | |

| HEIGHT | 40 cm |

| WIDTH | 46 cm |

| DEPTH | 46 cm |

| WEIGHT | 18 cm |

|

|

|

VIBRATORY ROUND SURFACE TREATMENT MACHINE |

|

| CAPACITY | 125 Litre |

| POLYURETHANE THICKNESS | 20 mm |

| STEEL THICKNESS | 6 mm |

| PROCESSING AREA WIDTH | 210 mm |

| INTERNAL DIAMETER | 700 mm |

| DISCHARGING HEIGHT | 950 mm |

|

|

|

INDUSTRIAL WASHING MACHINE WITH ROTATORY TABLE |

|

|

These are the machines used for washing when materials to be washed are

loaded to the rotating platform inside the cabin by using a loading

cart. Parts to be treated will undergo Washing, Rinsing, Passivization and Drying processes by means of a basked that turns around for 4 tours per minute on a horizontal axis. A machine suitable for the capacity and part dimensions will be designed. |

|

|

|

|

TITANIUM ANODIZING |

|

| Electropolishing is an electrochemical process to polish the metal surface, remove burrs and create a germ-free environment. | |

| Process selection suitable for the needs | |

| Very sensitive washing with 28 and 40 kHz frequency at the same time | |

| High quality stainless steel design | |

| Adjustable water heating feature with thermostat | |

| Powerful ultrasonic units with digital control | |